System Integration and Characterisation

This theme integrates our research outputs in energy harvesting, power management and wireless sensing. Combining the cutting-edge research in these areas, we deliver high-performance energy-autonomous systems that meet industrial needs in a wide range of applications. We have a full range of equipment to thorougly characterise the performance of such systems.

Our strain energy harvester (SEH) powered wireless sensing system is designed to harvest energy from structures experiencing dynamic strains (e.g. aircraft wings) to provide power supply for wireless sensors. We offer a complete high-performance system-level solution, including energy harvesting, power conditioning and wireless sensing, for a wide range of industrial applications.

The developed system integrates piezoelectric macro-fiber composite (MFC) onto carbon fibre laminates to harvest strain energy, and then converts the harvested energy into useable electrical energy via an adaptive power management module to provide electrical power for low-power-consumption wireless sensor nodes/networks, making them self-sufficient in energy supply.

We offer a complete system-level solution:

Strain energy harvester fabrication

- On curved and complex structures

- Vacuum-bagging method with out-of-autoclave curing process

Power management circuit

- Full-analogue maximum power point tracking controller with power consumption of 5-7 μW.

- Maximise the energy generation and transfer from the strain energy harvester to the energy storage

Energy-aware wireless sensor node

- No power-consumption at sleeping mode

- deployed with acceleration, humidity and temperature sensors presently

Key performance

Energy density: 0.075-0.188 mW/cm2 at a low vibration of frequency 4-10Hz with peak-to-peak strain of 600µε

Related Publications:

- Power Management Circuit for Wireless Sensor Nodes Powered by Energy Harvesting: On the Synergy of Harvester and Load

- Strain Energy Harvesting Powered Wireless Sensor System Using Adaptive and Energy-Aware Interface for Enhanced Performance

- Strain Energy Harvesting Powered Wireless Sensor Node for Aircraft Structural Health Monitoring

- Low power adaptive power management with energy aware interface for wireless sensor nodes powered using piezoelectric energy harvesting

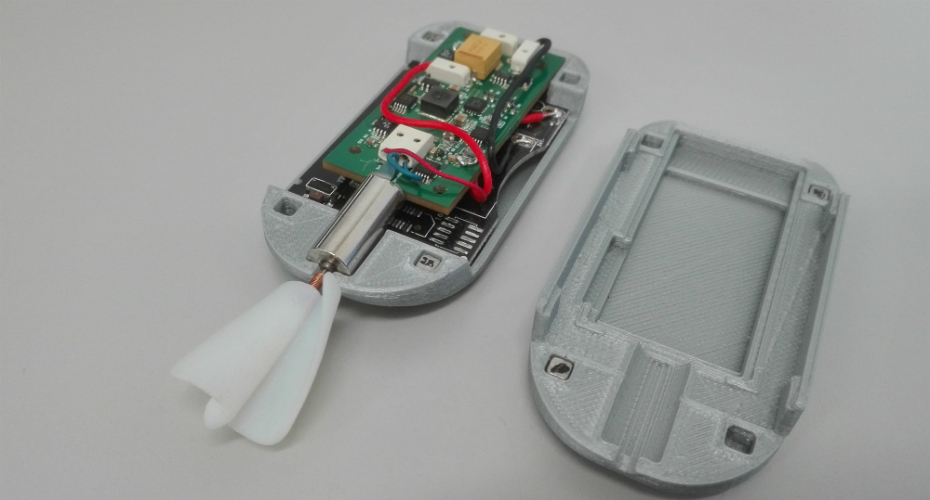

Our air flow energy harvester (AF-EH) is designed to harvest energy from vortices generated by high-speed objects (e.g. inside the vents and fairing of an aircraft), to provide energy sources for wireless sensors. It is able to continuously power a commercial Bluetooth-based wireless sensor node (WSN).

Key features

- Harvesting vortices instead of direct air flow streams, which introduces little dragging force and in some cases improve surface flow

- High energy output which is able to power the WSN continuously when air flow speed is greater than 16 m/s

- Versatile: the AF-EH can also harvest direct air flow streams if necessary

- Wide operational angle: the AF-EH can operate with air flows from ±90° relative direction to the turbine end facet

- Small size and lightweight: the AF-EH can be installed in small spaces as narrow as 15 mm and introduces little additional weight

Principle characteristics

Air flow energy harvester

Volume 4.15 cm3

Weight 13.4 g

Power 20–160 mW (10–18 m/s)

Able to continuously power the commercial wireless sensor node

Supplier Texas Instruments

Model CC2650STK

Protocol Bluetooth

Sensors 10 sensors: magnetic, humidity, pressure, light, temperature, acceleration, gyroscope etc.

Prototype animation

Our wearable knee energy harvester employing frequency up-conversion mechanism is able to produce enough electric power to enable the sensing and transmission of a battery-free wireless sensor node (WSN) for a range of physiological and motion sensing applications, such as fall detection and knee rehabilitation monitoring.

Key Features

- Frequency up-conversion mechanism converts the low-frequency human motion to the resonant vibrations of the piezoelectric materials (~ 250 Hz), to produce high electric power.

- Lightweight and unnoticeable resistance ensure the maximum comfort for the wearer.

- High electric power output is enabled by both the frequency up-conversion mechanism and high-efficiency power conditioning circuit

Principle characteristics

Energy Harvester

| Mechanism | Piezoelectric |

|---|---|

| Diameter | 90mm |

| Depth | 28mm |

| Weight | 100g (excluding braces) |

| Resistive force | <1.5N |

| Power | 4.5mW (walk at 5 km/h) |

Wireless sensor node (WSN)

| Protocol | Zigbee |

|---|---|

| Sensors | acceleration, temperature and humidity sensors |

| Sampling rate | 100 Hz (adjustable) |

| Duty cycle* | 15% (5km/h) |

| Transmission distance | <15m |

*ta/(ta+ts). ta: the time period that the WSN is sensing and transmitting; ts: the time that the WSN is at the sleeping mode.

Prototype animation

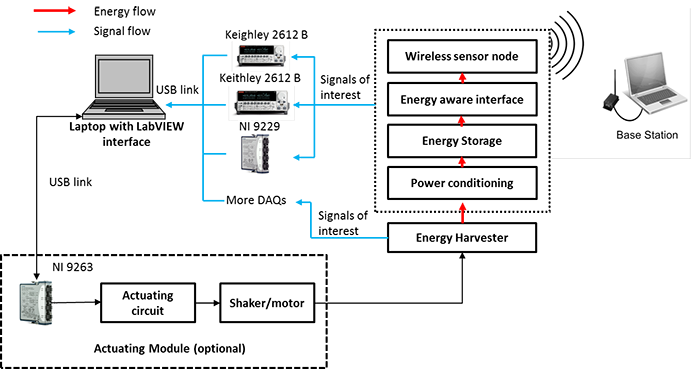

An end-to-end, system-level characterization testbed has been developed by combining a number of instruments through a LabVIEW interface. It is for on-line, real-time measurements of energy harvesting powered wireless sensing systems to characterise:

- energy distribution

- energy generation

- energy consumption

- system efficiency.

The testbed presently includes two system source meters and two data logs from National Instruments, which can take 12 current/voltage signals simultaneously and can be extended to include more data sampling channels when necessary. The operation of the hardware is coordinated by the LabVIEW interface on a PC, which is also deployed with functions including real-time data processing, analysis and display.