Using microwave metasurfaces to cook food

A case study by Cameron Gallaghera and John Bowsb

aUniversity of Exeter

bPepsiCo, Inc.

The problem

Conventional microwave ovens generate electromagnetic radiation in an enclosed cavity that couples into the food inside. The electromagnetic radiation heats the food through dielectric losses associated with the water content of the food and DC conductivity losses through dissolved salt ions. Food is heated passively albeit rapidly – that is, the resultant field distribution (and therefore heating pattern) results from the complex interaction of the field within the bulk food, leading to many undesirable and often unpredictable effects such as non-uniform heating, wetter or dryer surfaces, and cold spots not at the geometric centre. Additionally, different microwave ovens produce different heating effects.

For the food to be cooked predictably, the electromagnetic field distribution needs to be modified dynamically to allow selective heating of regions of the food to deliver targeted effects (from surface crisping to uniform heating) as well as improve efficiency of heating. The solution will need to be incorporated into food packaging and be cheap to produce or be long-lasting and reusable with different meals.

Our solution

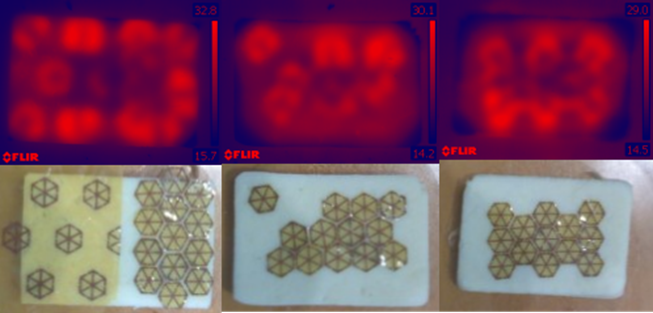

We explore the idea of electromagnetic metasurfaces designed with resonances at the operational frequency of standard microwave ovens when in the presence of a wet food material as a solution. These metasurfaces were placed beneath the food and heated in a microwave to see how the heat distribution differed from the no-metasurface case.

The resonances in the metasurface caused a localisation of the fields at the surface of the food that was in contact. This gives preferential heating of the food depending on the placement and density of the resonant elements of the metasurface.

Why use a metamaterial?

Different food items will have a different water loading and distribution, and, hence, a different refractive index. The variation in refractive index will mean that the resonant frequency for a specific design of metasurface will change depending on the water content in the food. Since metasurfaces are scalable, if a generic resonator shape is used then the resonant elements can simply be scaled for different foods to tune the metasurface resonant frequency to the microwave frequency.

Acknowledgements

The authors would like to acknowledge the funding made available from PepsiCo, Inc. which supported some of this work. The views expressed in this case study are those of the authors and do not necessarily represent the position or policy of PepsiCo, Inc.